The Mighty Palm

I’ve been methodically picking away at the design of these for a year now. I may fret over the design my entire life, but I’m happy to say I’ve got some lovely working prototypes now.

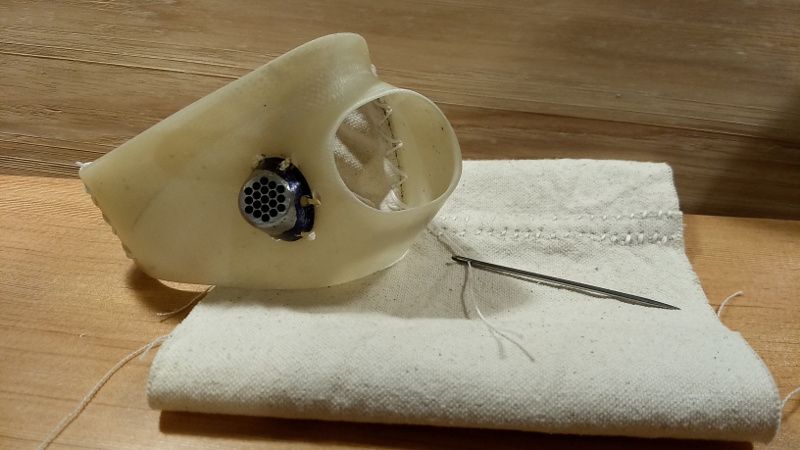

The inner layer of the composite and the back strap are both made of cotton fabric. The thimble eyes are a two-piece construction secured to the composite base with kevlar thread. It’s a little bit of a hack but it seems to work well. I’ve got a huge spool of carbon fiber tow sitting in the composites box, patiently waiting for some zany 3 A.M. weaving fixture idea to materialize. Also have a gajillion brass eyelets (min qty.) coming so we don’t have this, uh, humble thread-on-fiberglass situation everywhere-

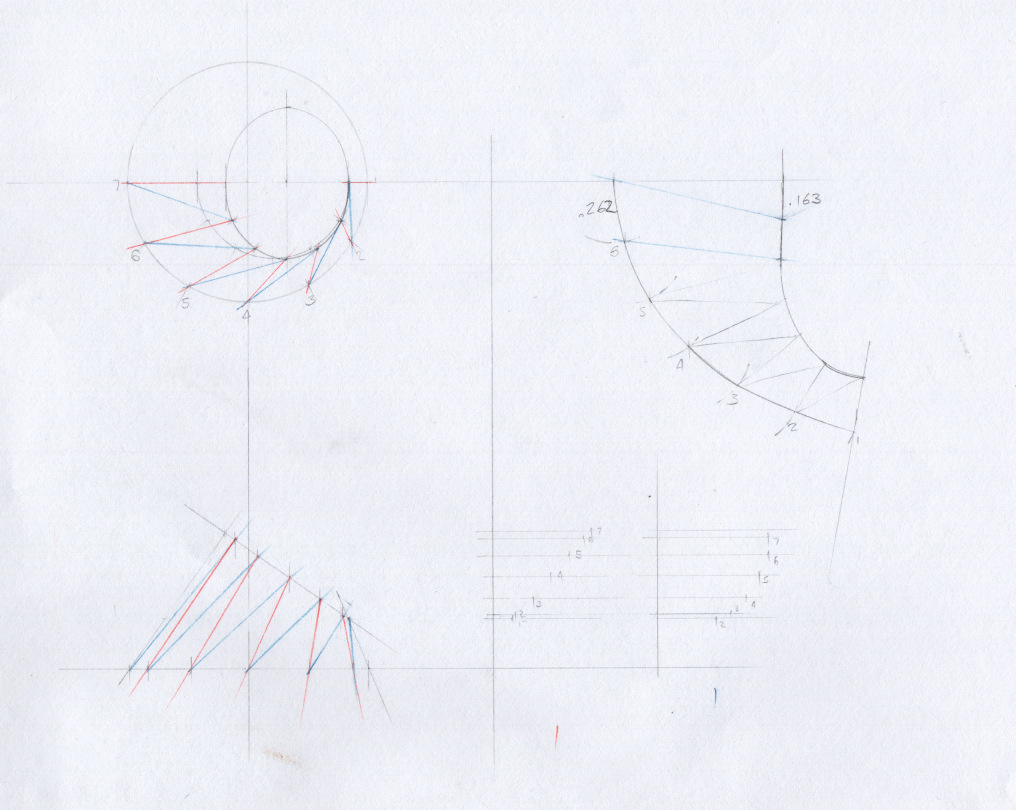

The thimble eyes are two pieces: a machined eye and a formed sheet metal flange. The sheet metal flange appears to be a truncated cone but it’s not- it’s a loft joining two pretty arbitrary circles. Fusion360 won’t ‘unroll’ a loft (come on, this is 2019!) so I cracked open my old drafting textbook and did it by hand:

Then I made a template from the drawing, applied geometry! I tested it out on .025” mild steel but ultimately have made all the flanges of thicker 14? ga. steel. I need to make a tool to bend these precisely, the hammer is fun but time consuming.

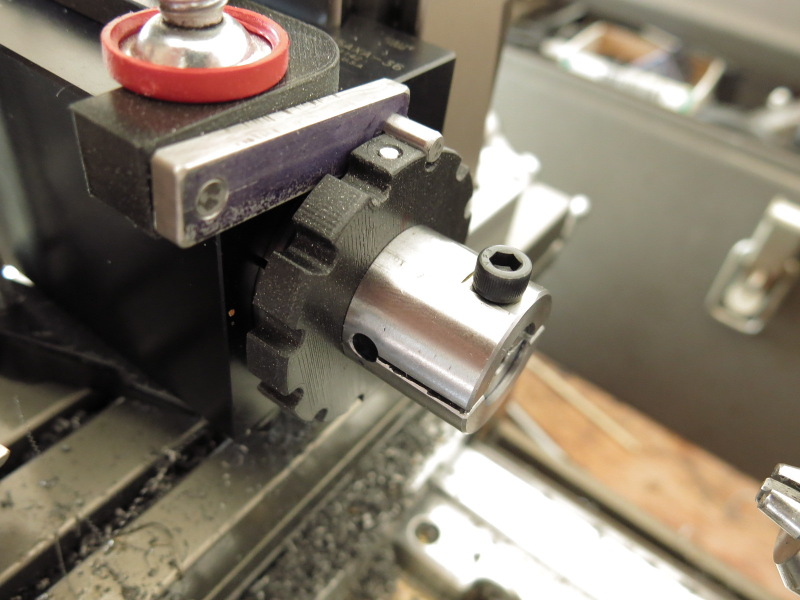

I wanted a dense pattern of crisp divots in the eye of the palm. This is the heart and soul of the palm after all- I made a fixture to index the holes, with the help of the 3D printer to make the indexing ring:

Here is the result- They really grip the needle well, even at very steep angles. This is desirable when you’re pushing the dull end of a needle towards your hand with all your might. It also just makes sewing easier and faster. Because the needle-pressing surface is the highest point around it, you can push the fat eye of the needle right into the fabric. Usually this is a second (precision) operation with a rawhide-covered palm.

The eyes need to be joined to their flanges. For the first few I enlisted my calmest tig-welding friend Karl- to make it easier for him I made a little fixture:

He did a solid job for only having relatively giant 1/16” filler- a day later I realized these are perfect for furnace brazing though. So I got off my butt and finally finished building my HT oven. Stay posted for pics of that :)