Apartment Woodworking

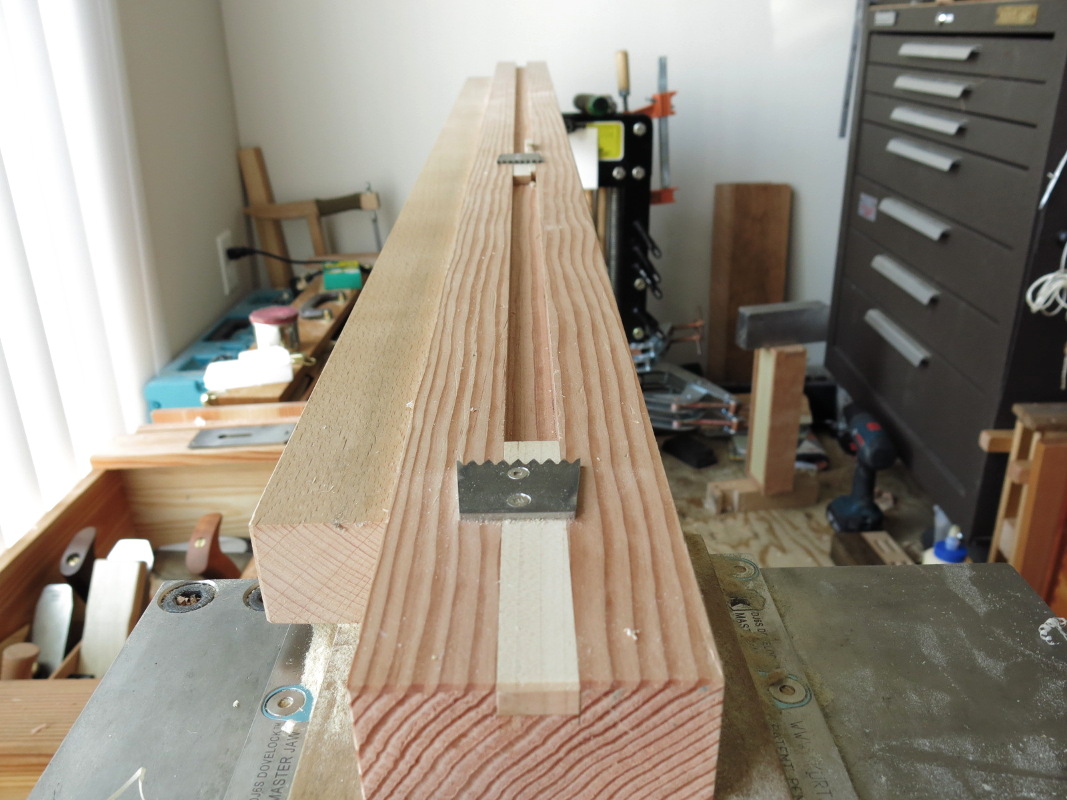

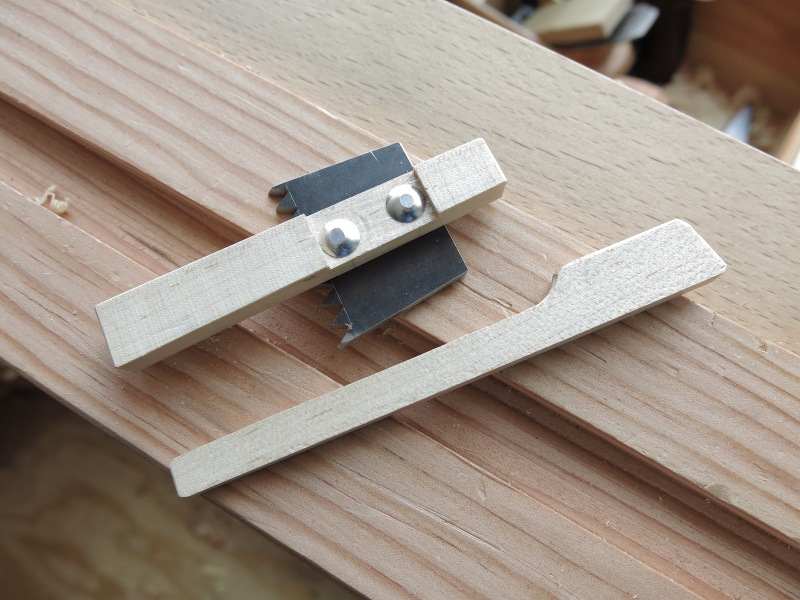

The tiny apartment shop is picking up steam. I’m preparing to build a sort of bowl-turning lathe of wood, and it’s become a very hands-on project. I made this saw vise so I can sharpen the saws I use to cut up the pieces. It’s sort of the japanese style of vise adapted for western saws and made of scraps.

I wanted a heavy full-sized workbench but didn’t really have the space to keep it. Inspired by the planing beam in ‘Japanese Woodworking Tools’ I came up with this-

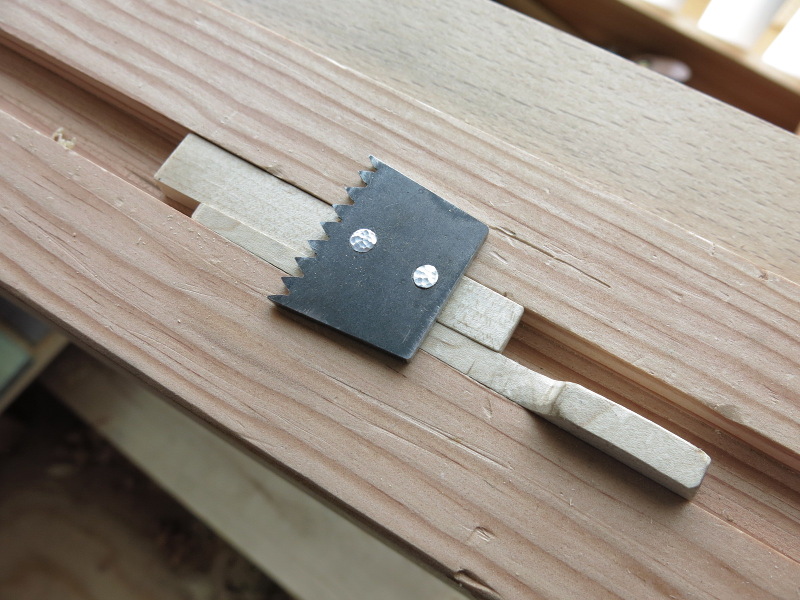

A lot of the appeal of a big workbench are the vises and holdfasts. Clearly a vise wouldn’t be very useful attached to this beam, so I came up with this wedged planing stop in a groove thing, it works really well. The beam might be even better than a bench–I can plane to thickness down to 1/8”, then joint the edges using the side rail, then dimension with a splitting gauge or rip saw, and then rabbet or plow without hardly having to move the stock. When I’m not planing I just stand it up in the corner. It’s about 6’ long, with a straight-grained and well-behaved 4x4 for the guts and a 2” wide side rail screwed to it. Screwed so it’s removable for trueing.

Been trying to speed up the sharpening process. The closer I am to a stone, the more peaceful the work is. I hardly care what kind of stone I’ve got, as long as it’s near and watered. I arranged some diamond plates under my vise in the Paul Sellers style- when they wear out too soon I’ll probably replace them with some hard waterstones (like the green one)

Here are some scales and a sheath for a Hock marking knife. Machined the rivets of copper. I had been using a snap blade craft knife but was really curious if a single bevel would make for tidier work. It does, but only a small difference.

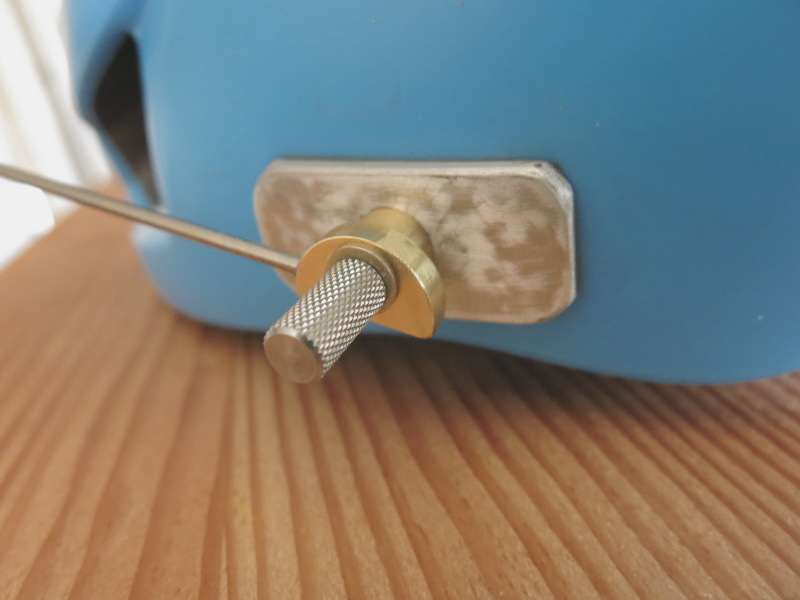

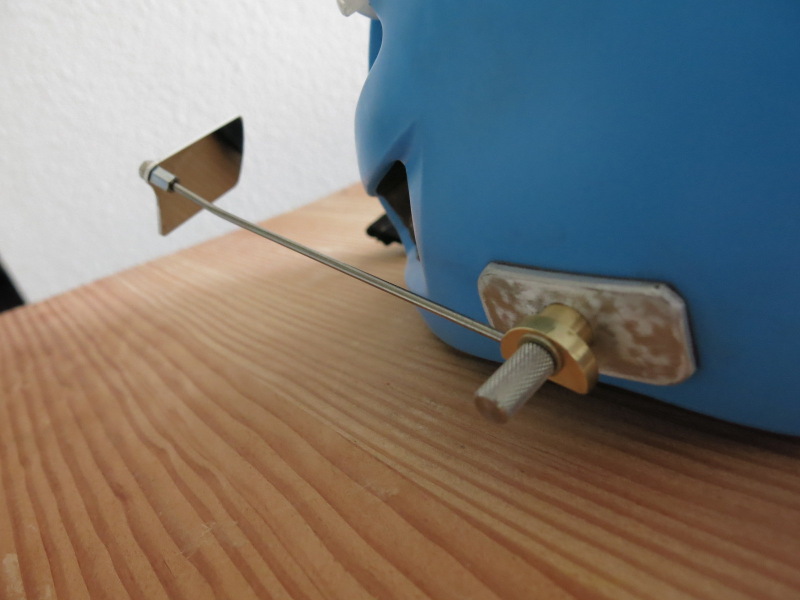

Lastly, unrelated, a helmet mirror made of an old hard drive platter, some scraps of metal, and a bicycle spoke:

The thumbscrew allows it to pivot up out of the way, or I can take it off when I go mountain biking.